1. World’s longest submarine OSP fiber route: 39,000 km

The SeaMeWe-6 (Southeast Asia – Middle East – Western Europe) project is a 39,000 km long submarine OSP fiber network linking 19 countries across 3 continents. It includes extensive OSP landing segments connecting the undersea system to terrestrial networks. Designed to deliver over 100 Tbps of capacity using next-gen OSP technology.

2. OSP fiber installed at record-high altitudes

OSP fiber cables have been laid in the Himalayas, reaching altitudes above 5,000 meters (16,400+ feet). One project in Ladakh, India involves laying over 1,800 km of fiber through ice, snow, and permafrost, requiring OSP cable jackets rated for extreme cold and shifting terrain.

3. Google fiber’s OSP microtrenching innovation

To accelerate FTTH OSP deployment in urban areas, Google Fiber pioneered microtrenching-cutting narrow grooves (as little as 0.5 inches wide) into pavement to install fiber. This reduced construction time and disruption by over 60% in cities like Austin and Salt Lake City.

4. OSP fiber and space missions

NASA uses OSP fiber links to connect ground-based operations with deep-space antennas. Facilities like Goldstone Deep Space Communications Complex in California rely on ruggedized OSP networks to support communications with probes billions of miles away.

5. High-speed rail relies on OSP fiber

Countries like Japan and China run OSP fiber cables along high-speed rail tracks, often stretching thousands of kilometers, to provide high-speed Wi-Fi, real-time rail diagnostics, video surveillance and automation. Trains traveling at 300+ km/h stay connected seamlessly through this infrastructure.

6. OSP fiber in extreme climates

In the Middle East and Africa, OSP fiber has been successfully deployed in desert environments with surface temperatures exceeding 60°C (140°F). Special thermal-resistant cable jackets and sand-resistant enclosures are used to withstand extreme UV and dust.

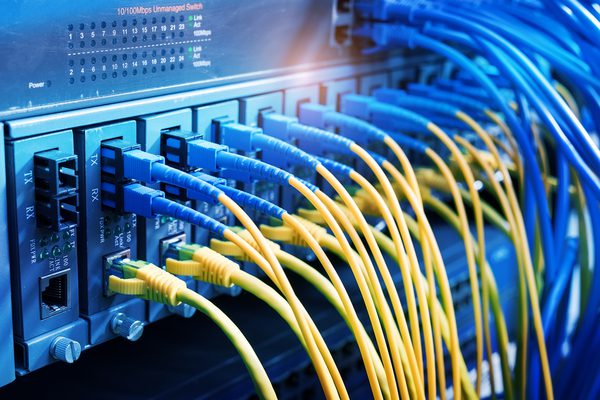

7. OSP fiber data speeds hit 1.2 tbps in field tests

In a record-setting demo, Ciena and Verizon transmitted 1.2 Tbps over a live OSP fiber link spanning over 900 km in the U.S. This demonstrated the potential of OSP to handle growing demands without replacing existing fiber-just upgrading optics.

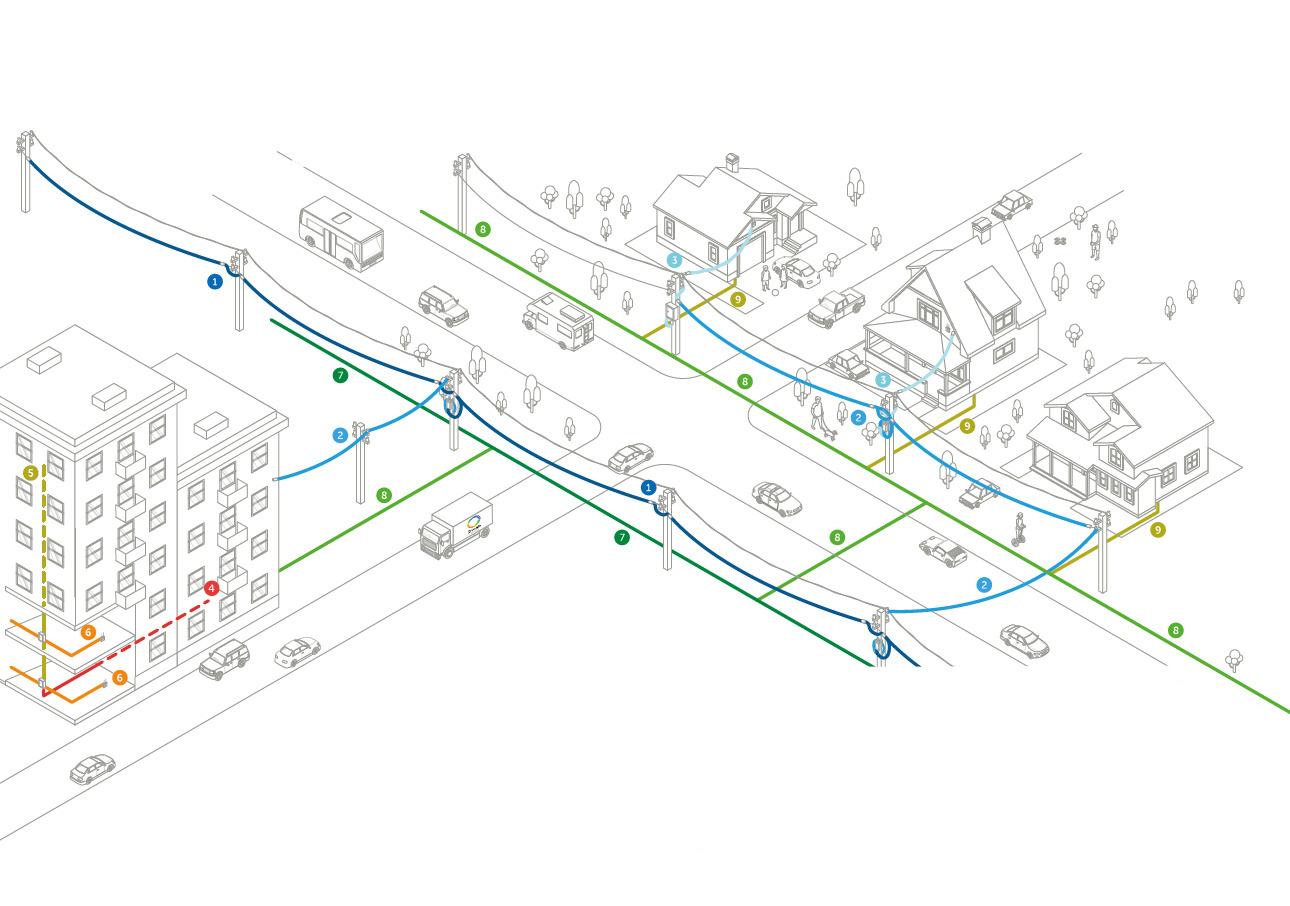

8. OSP mapping in augmented reality (ar)

Utilities and telecom companies now use AR headsets to visualize underground OSP cable routes before digging. This reduces accidental damage and speeds up troubleshooting-especially in dense urban corridors.

9. AI-powered OSP maintenance

AI models now predict OSP fiber faults (e.g., microbends, moisture exposure) before they occur, using data from smart splicing enclosures and environmental sensors. Preventative OSP maintenance is estimated to reduce downtime by over 40% in large-scale deployments, saving tens of millions of dollars.

10. OSP networks power renewable energy grids

Many solar and wind farms rely on OSP fiber to interconnect control systems, SCADA devices, and substations spread across vast, remote regions. In some projects, one fiber route spans over 3,000 km, ensuring power grid responsiveness and automation.

Don't hesitate! Start using splice.me

Create, manage, control all your fiber splicing in one place, fast and easy