Outside Plant (OSP) in fiber optics is the network infrastructure located outside of buildings. This means cables, conduits, ducts, poles, splice enclosures, cabinets, handholes, aerial or buried fiber right up to the demarcation point between outdoor and indoor plant.

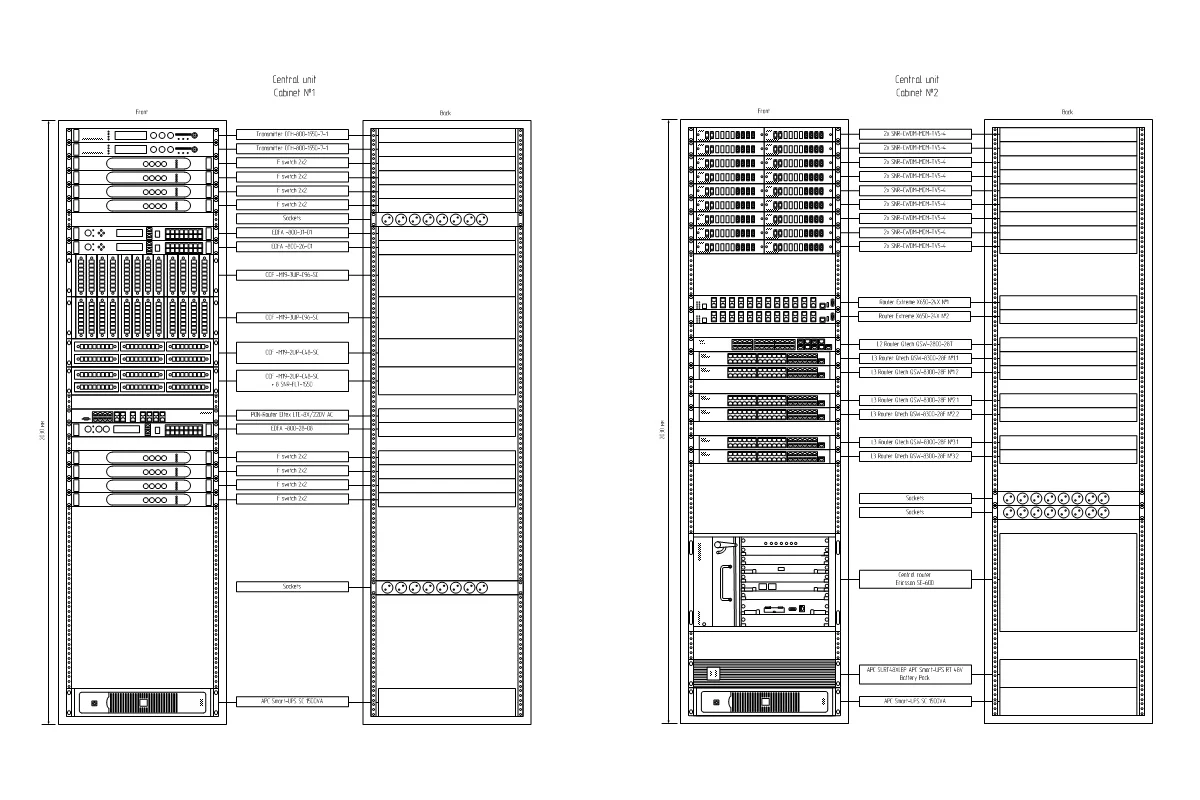

Inside Plant (ISP) in fiber networks is the cabling and equipment inside buildings – cabinets, patch panels, fiber cabling, routers, power supplies, and internal networking gear.

Network operators may imply that all cabling and equipment, located outside of their central network office, including one located in-house on user’s side, is referred to OSP. On the other hand, network operators may imply that a 300 ft outdoor fiber cable, connecting two central server rooms in adjacent buildings, is referred to ISP. However, the National Fire Protection Association (NFPA) stipulates that OSP cabling must be terminated within 50 feet (15 meters) from where it enters the building, whether through a wall or the flooring. So there should be a clear demarcation point where transition happens and where outside cables enter the building of the central office.

Differences between OSP and ISP networks

OSP runs outdoors. It means it is exposed to weather – rain, extreme temperatures, corrosion, rodents, UV, and requires robust cable protection – steel armor, water‑blocking layers, aramid fibers, to maintain performance despite harsh conditions, moisture and high and low temperatures, resists abrasion and tearing, and even permafrost heaving. OSP cables are installed overhead on utility poles, underground in ducts and conduits, directly buried.

ISP runs in-house – inside controlled environments, with minimal environmental stress and simpler cable jackets and flame‑retardant build. That’s why ISP fiber cables are usually lightweight, with thin jackets, designed for flexibility and ease of use inside racks and risers.

OSP cabling is engineered for long‑distance transmission – between hierarchically different network nodes, connecting buildings, neighborhoods, and cities. Hence single‑mode fibers dominate OSP applications. ISP cabling handles short‑distance runs within buildings, so one can find single- and multi-mode fibers used, as well as ribbon-type cables, various unusual connectors an other interesting stuff.

Planning and design of OSP and ISP

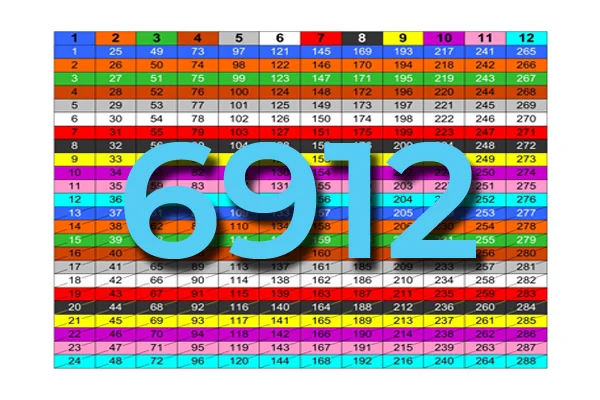

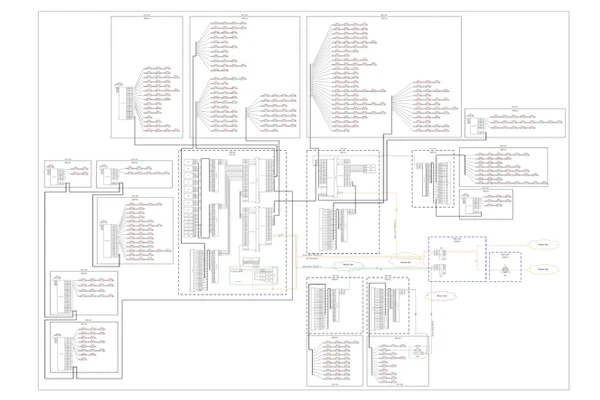

Both outside plant and inside plant fiber optics use same basic principles of light transmission. And both of them require good documentation. It means a good outside and inside fiber plant have precise cable route plans, equipment allocation plans, fiber splice matrixes, link loss budgets, BOQs, test reports, everything – to support installation, maintenance, and expansion.

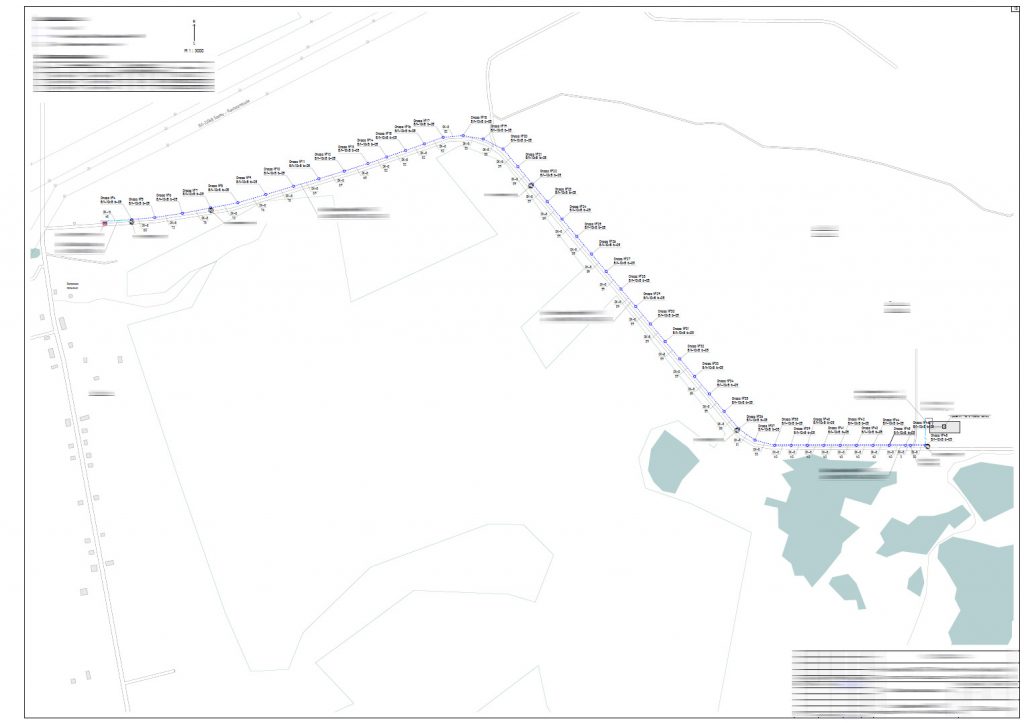

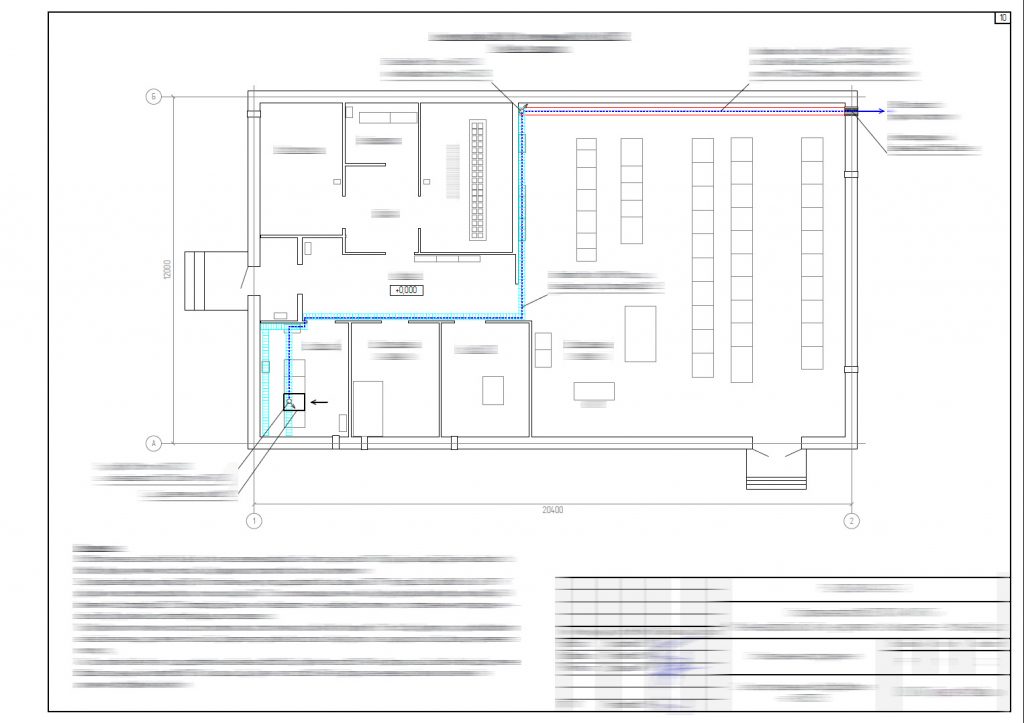

The major difference is the fiber cable mapping. In OSP applications, the terrain map is the key document of the whole project. Specific standards and regulations apply to it. Key ISP design documents are floor plans – with their own standards and regulations.

OSP maintenance & ISP management

When it comes to maintaining and managing fiber optic cabling, outside plant and inside plant each come with their own sets of practices and responsibilities.

OSP maintenance includes periodic inspections of aerial cables and underground cable paths, checking for physical damage from weather, animals, construction, or vandalism. Technicians also need to monitor signal gain over distance, which may degrade over time due to splicing issues, water ingress, or fiber bending. Utility poles, manholes, and splice enclosures are routinely inspected and tested for structural integrity. Vegetation management, such as trimming trees near aerial lines, is also a routine part of OSP work. OSP networks often include a GIS-based asset management and monitoring systems to log the location, online status, and service history of fiber routes.

On the ISP side, management involves regular cleaning of fiber connectors, inspecting patch panels, and maintaining an organized labeling system Environmental conditions like temperature, humidity, and dust are carefully monitored. ISP fiber systems are more prone to issues from equipment changes or reconfigurations, which means thorough documentation and change control processes are critical. It may surprise you, but among other things, keeping track of server rooms doors being locked is one of the factors, that can prevent 90% of other issues in inside plant fiber networks.

Why you can’t use Inside Plant rated cables in Outside Plant?

Let’s look at a situation as follows – your fiber project team presumes that ISP rated fiber cables will perform adequately when used outdoors, provided they are sufficiently protected. They also rely on the belief that conduit alone is sufficient to safeguard such cables. However, this assumption overlooks the reality that structures naturally move and settle over time. As buildings age and ground or concrete shifts, conduits can suffer damage. If a conduit cracks, water may infiltrate. In cases where ISP rated cables are housed within these conduits, complications arise: these cables are not designed to withstand moisture. The outcome? Damaged infrastructure and costly replacements for both cabling and conduits.

Additionally, temperature fluctuations can negatively affect ISP rated cables installed in OSP domain. For instance, when ground temperatures are cold but surface conditions are warmer, condensation forms beneath the concrete slab, accumulating moisture in the conduit. Even if the conduit itself remains undamaged, this moisture can compromise ISP rated cables over time.

Conduits installed beneath concrete slabs introduce further challenges, as they often face water ingress caused by natural occurrences or human mistakes. For example, conduits rising from the slab at the lowest point of a building, e.g. in a basement, are particularly susceptible to flooding from excessive rain, plumbing failures. If this flooding enters the conduit from above and water remains trapped inside, indoor-rated cables will eventually degrade.

Unless monitored closely, problems remain hidden until major performance issues emerge. Measures like sealing and pressurizing conduits are often impractical or too expensive for network operators.

Outdoor-rated OSP cables vary by type, each designed for distinct applications. Selecting the appropriate OSP cable requires considering multiple industry standards. TIA standards includes references to relevant guidelines for harsh environments as well as performance benchmarks, outlining minimum requirements for OSP facilities.

Labeling OSP and ISP fiber cables

- Every cable, termination, and pathway must be labeled clearly and consistently.

- Labels must be machine-printed and durable, using thermal or laser printers (though some regulations allow handwritten labeling).

- Labels should be permanent, resistant to moisture, chemicals, abrasion, and UV where applicable.

- Near terminations – at both ends of the cable (patch panel, distribution frame, wall plate, equipment).

- At every intermediate transition – where a cable changes pathway (e.g., enters a riser, conduit, or cable tray).

- Visible intervals – typically every 10–15 feet (3-5 meters) in accessible trays or pathways for ISP builds.

- At each pole, messenger clamp, or support point – use weather-resistant tags or embossed metal plates.

- At span junctions and mid-span slack points – identify cable ID, route name, and direction.

- Closures – label every cable entering a splice closure.

- Cable ends at buildings or terminals – label immediately where cable enters or terminates.

- At every handhole, vault, or manhole – label inside lid and on cable near splice closure.

- At every splice case – durable label inside closure and external tag if applicable, usually a metal tag attached by metal wire.

- At cable entry into buildings or cabinets – mark per NEC 770 and fire-rating requirements.

- Along cable path – set up a small signal poles each 500 ft along cable path and at each cable path turn.

- Above buried cable – marker tape or tracer wire should be installed 12-18 inches above fiber for detection and location.

Blowing fiber in OSP and ISP applications

Blown fiber, also called blow-in fiber, is a method used to install optical fiber cables by propelling them through small plastic tubes called microducts using compressed air. This technique has become increasingly popular in both outside plant and inside plant environments because it offers scalability and cost-efficiency.

In OSP applications, this approach allows network operators to build out infrastructure in stages. For instance, ducts can be installed throughout a neighborhood or city in advance, and fiber can be blown in only as new homes or businesses request service. This means providers avoid wasting time and money on unused fiber capacity, and they don’t have to dig up roads or retrench every time they want to connect a new customer.

ISP use of blown fiber works similarly, though on a smaller scale. In data centers, commercial and multi-dwelling buildings, where space is tight and change is often, blown fiber enables installers to set up microducts through riser shafts, ceilings, or cable trays and later install the exact number of fiber strands needed. This eliminates excess slack storage, minimizes cable congestion, and makes future upgrades or reconfigurations much easier.

Fiber bend radius in OSP and ISP applications

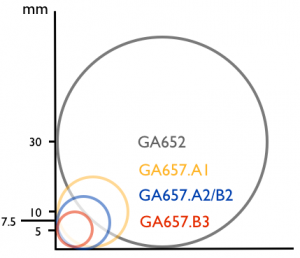

The minimum bend radius is the tightest a fiber cable can be bent without risking performance loss or breakage. When this limit is exceeded, the glass core can fracture, light can leak out of the core, causing signal attenuation. Long-term reliability is compromised due to material fatigue. And for high-speed long-haul networks, even slight bends can cause measurable signal loss.

In ISP environments, challenges include routing fiber through high-density trays, patch panels, or conduit with tight turns. Small wall outlets, floor boxes, furniture-mounted outlets in enterprise spaces pose the need for tighter bends. That’s where RBS (reduced bend sensitivity) or bend-insensitive fiber comes very beneficial. With RBS fiber, installers can bend cables around corners or within small enclosures without introducing ignal losses, which reduces installation constraints.

In OSP environments, bend issues arise during pulling fiber through long duct routes with multiple direction changes, in slack storage in handholes or aerial splice enclosures, and in cold-weather installation where the jacket becomes stiffer and more prone to damage if over-bent. Obviously, bend radii in OSP applications should not be that tight, but surprisingly RBS fiber also is vastly used here. It is often applied in modern fiber distribution hubs and closures with compact slack loops, tight duct runs in congested utility rights-of-way, microduct or blown fiber systems where sharp entry/exit angles are unavoidable.

Conclusion

Understanding OSP (outside plant) and ISP (inside plant) is foundational to designing, deploying, and managing fiber‑optic networks – from the rugged outdoor cabling that connects neighborhoods to the sleek building infrastructure that connects servers and routers. While OSP demands ruggedized cables and environmental resilience, ISP focuses on efficient distribution within buildings. Together, they form a cohesive cable plant system when properly designed, documented, deployed, and maintained.

Read more:

4 key components of FTTh network design

FTTH Planning and Design 101

Take care of your splice sheets

1000+ ISPs are already saving weeks of work with Splice.me!