Introduction

Unfortunately, time flies quickly, and it will soon be half a century since the beginning of the era of wired communication via optical fiber (OF). Today, fiber optic cables (FOC) are the most important component of the modern global communication network, providing a wide variety of telecommunication services and total informatization of society. The global market for the production and consumption of OF, which originated in the 1970s, is estimated at over 500 million km.

The idea of fiber optic communication is far from new and has been on the radars since the beginning of the last century. However, the use of fiber optics for communication over a distance of at least one kilometer has long been questioned. The reason for this was the insufficient transparency of any known materials. The first candidates for the basis of optical fibers were most often various glass-forming materials, or, simply put, glass.

In the work of Kao, who later received the Nobel Prize along with other creators of optical fibers, it was theoretically predicted that in an optical fiber made of sufficiently pure quartz glass (chemical composition SiO2, excluding impurities), the attenuation coefficient could be less than 20 dB/km, which meant a real practical possibility of building a fiber-optic transmission system (FOTS). Due to the unique set of properties of quartz glass, fibers based on it have all the necessary characteristics that allow it to be successfully used in telecommunications. But the aforementioned attenuation of 20 dB/km is of course an outdated value today. Modern single-mode fibers typically have attenuation of less than 0.25 dB/km at wavelength of 1550 nm.

The most common fiber type is standard single-mode fiber

Assuming that readers are well aware of the difference between single-mode and multimode fiber, let’s note that the most widely used fiber is the so-called «standard single-mode fiber» (apparently more than 95% of the total amount of fiber optic cable produced and laid worldwide is single-mode and will most likely remain so in our lifetime). We will consider the recommendation G.652 of the International Telecommunication Union (ITU) to be the fundamental technical standard here. We should emphasize that the requirements for certain parameters (attenuation coefficient, polarization mode dispersion, etc.) in this document are currently quite «liberal» and lag significantly behind the long-established global standards of leading optical fiber manufacturers. For example, G.652 allows an attenuation coefficient of 0.4/0.3 dB/km at wavelengths of 1310/1550 nm, while the current standard is 0.36/0.22 dB/km.

The most conservative and strictly standardized parameter of this typical design is the so-called cladding diameter, whose standard value is 125.0±0.5..0.7 μm (the tolerance of ±1 μm according to ITU-T G.652 should be considered obsolete, in our opinion). The next established parameter is the coating diameter, which is always two-layer. The need for two layers is due to a number of reasons, primarily related to the requirement to ensure low fiber attenuation, especially at low temperatures. For about 40 years, the materials used for the protective coating have been UV-curable (cured by ultraviolet radiation) urethane acrylates (inner layer) and epoxy acrylates (outer layer) – polymer materials specially developed for this purpose. The diameter of the outer layer of the protective coating (without external coloring) is most often in the range of 235–250 μm, and is not specifically regulated by ITU-T. The diameter of the inner layer is also not standardized, but is usually close to 200 μm.

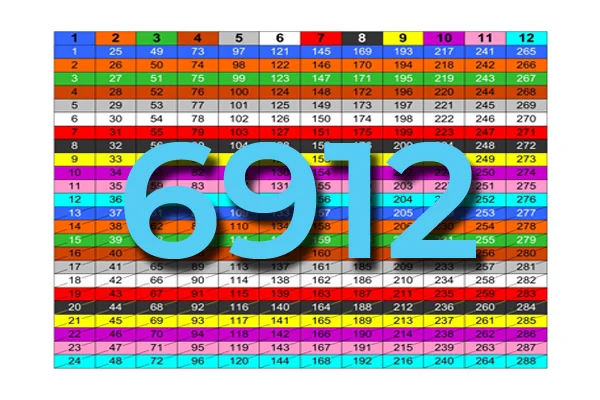

Since fiber optic communication cables can contain several dozen or even hundreds of fibers, they must be distinguished and identified in some way during. For this purpose, fibers are usually colored. UV-curable «ink» is used as a coloring material. The thickness of the coloring coating is usually about 5 μm. Thus, the colored optical fiber has a final outer diameter approximately 10 μm larger than the uncolored one, i.e., approximately 245–255 μm. It is also worth mentioning the fiber coloring technology used by some manufacturers, which involves coloring the outer layer of the fiber directly during the fiber manufacturing process (colored on draw). In addition, the basic colors may not be sufficient to distinguish between fibers during the installation of fiber optic cables, so special “printed” ring marks can be applied to the fibers using appropriate equipment.

Read more: Brief history of fiber cable color codes

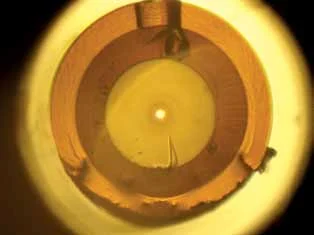

Pic.1. A rough cross-section of a typical single-mode optical fiber (unpainted) viewed under an optical microscope.

Pic.1 shows a cross-section of a typical optical fiber (uncolored) when viewed under a conventional optical microscope. The visible «defects» on the end surface are due to the fact that the optical fiber was cut manually using the simplest tools. The bright illuminated spot in the center is actually the core, the lighter area is the 125 μm shell, and further towards the periphery is the two-layer protective coating (acrylate). The layers of the shell appear brown here due to the strong absorption of light in the coating material. When illuminated from the side, the uncolored protective coating appears almost transparent and colorless, sometimes slightly yellowish in the case of long-term storage.

Fiber is supplied to cable factories producing fiber optic cables in lengths from 2 to 50 km, colored or uncolored, wound on a reel (the approximate size of the standard reel is 200 x 300 mm) and packed in boxes of 4–6 reels. The linear weight of fiber is approximately 60–70 g/km, so 50 km of fiber on one reel weighs about 3 kg.

The described design of single-mode optical fiber was developed simultaneously by many manufacturers in the US, Japan, and Europe in the 1980s. It is essentially de facto standardized (hence the title of this article) and is the most widespread.

Fiber without the water peak is the «new standard»

An important milestone in the era of fundamental improvement of standard OF was the development of «water peak-free» fiber around 1998 , as a result of which G.652 optical fiber, which previously operated only in the 1310 and 1550 nm wavelength ranges, became «all-wavelength» and now allowes transmission at any wavelength from 1270 to 1625 nm. This achievement was «legislated» in the new editions of the G.652 recommendation (after 2000) with the introduction of categories A/B/C/D. Categories G.652.C/D differ from G.652.A/B that they contain requirements for the maximum allowable attenuation at the «water peak» (1383 nm), which now must not exceed the attenuation at 1310 nm, i.e., be no more than 0.4 dB/km. Categories «C» and «D» differ from each other only in the requirements for polarization mode dispersion (PMD). Apparently, in many practical applications, this difference is insignificant, but formally, category «D» is still more stringent.

With the emergence and establishment of «water-peak-free» optical fibers over the past 20 years or so, the concept of «standard single-mode fiber» has gradually taken on a new meaning. The «water peak» has been displaced not only from the design of optical fibers, but also from the global market in many regions. Thus, G.652.D is currently the most widely used fiber. Today, it is difficult to find G.652.A/B fiber, except in optical cables that were installed quite a long time ago.

Perfection of the already perfect

We now refer to G.652.D as the «standard optical fiber», not just to G.652. But the evolution of the most widely used optical fiber did not stop there. It would seem that by around 2010 it’s design had reached perfection and there was nothing left to improve. But, as everywhere else, competition forces manufacturers to continue to improve, to create something new or «seemingly» new.

Let’s return back to attenuation. Pure quartz glass, without alloying additives, has a light transmission range of approximately 160–3500 nm, with the lowest attenuation occurring at a wavelength of about 1560–1570 nm. It should be noted that special fiber designs (ULL class – Ultra Low Loss) with an attenuation coefficient of ≤ 0.15–0.16 dB/km were also created, without alloying additives in the core. Such optical fibers are, first of all, very expensive to manufacture. As for the widely used and relatively inexpensive (up to $10/km) standard optical fiber, it’s design always includes germanium (and possibly phosphorus, boron, etc.) additives necessary to ensure the required refractive index profile of the core. However, the essential presence of germanium in the core leads to some additional light scattering, as a result of which the practical (and probably theoretical) limit of the minimum possible attenuation of an OF, as studies show, is somewhere in the range of 0.177–0.179 dB/km at 1550 nm wavelength.

Thus, without considering special expensive fiber optic cable designs with a pure quartz core, we note that the best examples of mass-produced standard fiber (with a germanium-doped core) have an attenuation coefficient very close to 0.18 dB/km. To be more precise, commercial fibers of this type, sometimes conditionally classified in a special «LL» (Low Loss) group, often have an attenuation coefficient in the range of 0.180 ± 0.002 dB/km. This appears to be the attenuation limit for standard single-mode optical fibers at 1550 nm wavelength.

Standard, universal, and all-in-one

- similar in characteristics to standard fiber

- but with reduced attenuation

- and with lower sensitivity to bending

- and seamlessly spliced (without steps on reflectograms) with standard fiber

| Category / Parameter | G.652.D | G.657.A1 | OFS AllWave OneZWP | Corning SMF-28 Ultra |

| Cladding diameter, μ | 125 ± 1 | 125.0 ± 0.7 | 125.0 ± 0.7 | 125.0 ± 0.7 |

| Sheath diameter, μ | – | – | 240 ± 5 | 242 ± 5 |

| Mode field diameter at 1310 nm, μ | (8.6 – 9.5) ± 0.6 | (8.6 – 9.5) ± 0.4 | 9.2 ± 0.4 | 9.2 ± 0.4 |

| Attenuation coefficient at 1310/1383/1550/1625 nm, dB/km |

0.4 / 0.4 / 0.3 / 0.4 | 0.4 / 0.4 / 0.3 / 0.4 | 0.33 / 0.29 0.18 / 0.20 |

0.32 / 0.32 0.18 / 0.20 |

| Chromatic dispersion (max. at 1550 nm) | ≤18 | ≤18 | ≤18 | ≤18 |

| Polarizition mode dispersion (LDV), ps/km^2 | 0.2 | 0.2 | ≤0.04 | ≤0.04 |

| Attenuation at bending, dB 100 coils R=30mm at 1625 nm |

≤0.1 | – | ≤0.01 | ≤0.01 |

| Attenuation at bending, dB 10 coils R=15mm at 1550 nm, 1625 nm |

– / – | 0.25 / 1.0 | ≤0.05 / ≤0.3 | ≤0.05 / ≤0.3 |

| G.652.D compliance | – | – | Yes | Yes |

| G.657.A1 compliance | – | – | Yes | Yes |

Table 1 compares the requirements of the latest versions of G.652.D and G.657.A1 for some key parameters of optical fibers. The table also provides some basic parameters of «universal» optical fibers from two leading manufacturers. It is up to the reader to draw conclusions about the compliance of the characteristics with regulatory documents and standards, and about the advantages of one type or another of optical fiber and manufacturer.

It should be noted that today some manufacturers of optical fibers and cables emphasize the «versatility» of this latest development, highlighting such qualities as reduced attenuation, smoother spliceability characteristics, reduced losses on macro- and micro-bends, and the ability to operate in an access network at reduced but moderate (R≥15 mm) bending radii. However, perhaps the ultimate criterion for the technical and economic efficiency of its use will be the price, i.e., if universal optical fiber has a price close to that of standard optical fiber of «older» generations, then it will have a better chance of becoming as widespread as standard optical fiber. And thus, the concept of «standard optical fiber» will once again take on new meaning.

A few more words should be said about OF with a protective coating diameter of 200 μm. Today, there are both «Flex-like» representatives of this group and «universal» FO on the market, which differs from its basic version only in the diameter of the coating (also two-layer): 200 μm instead of 250 μm. The reduced coating diameter makes it possible to produce thinner cables, thus saving scarce space in cable ducts, pipelines, etc. The extent to which this solution will become widespread in the future is not yet entirely clear. Nevertheless, FOC with 200 μm fiber is already being offered by some manufacturers.

Conclusion

In today’s global terrestrial telecom network, the most widespread and widely used is «standard» single-mode fiber, which complies with the G.652.D standard. There is a trend towards wider use of «universal» OF, which complies with the most popular G.652/G.657 ITU-T standards, and are suitable for both the backbone networks and most segments of the access networks at the same time. The technical and economic efficiency of the mass use of «universal» optical fiber may require further justification. The most common criterion for the feasibility of using a particular type of optical fiber in a network is usually its price.

Take care of your splice sheets

1000+ ISPs are already saving weeks of work with Splice.me!