Unusual & record-setting splicing scenarios

Extreme environment splicing

– Splicing in Antarctica?

Yep. Research teams in the South Pole use ruggedized splicing equipment in -40°C weather to maintain communication lines to orbiting satellites.

In deserts, splicing crews have reported needing to cool down machines in ice chests to prevent overheating.

– Undersea fiber splicing by robots

When subsea fiber cables are damaged – whether by sharks, anchors, or earthquakes – splicing is done by robotic submersibles on the ocean floor. These autonomous systems make splices thousands of meters deep, sometimes in total darkness and crushing pressure.

– Fiber splicing in space?

NASA has explored laser-fused fiber splicing as a future technology for orbital communication relays. One proposed use is for in-space manufacturing of long-range optical tethers.

The tiny torch: how fusion splicing works

Fusion splicing uses an electric arc to melt and fuse two fiber cores – often made of ultra-pure glass about 9 microns in diameter. For perspective, that’s about 1/10 the width of a human hair.

Steps:

- Strip the protective jacket and buffer

- Clean the fiber with isopropyl alcohol

- Cleave the glass with a diamond blade

- Align the cores using an automated

- ore-alignment splicer

- Fuse with an electric arc

- Test for insertion loss and reflectance

"Splicing olympics"

Some large ISPs hold internal competitions – dubbed “Splicing Olympics” – where techs are judged on:

- Splice time

- Loss levels

- Number of redos

- Durability after stress testing

Splicing mistakes that made history

In 1998, a misaligned splice caused a 3-hour internet outage across parts of the U.S. East Coast. The splice passed initial testing, but failed under thermal expansion.

A fiber patch left unspliced in a vault once caused a $400M satellite launch delay due to broken telemetry.

Fiber splicing by the numbers

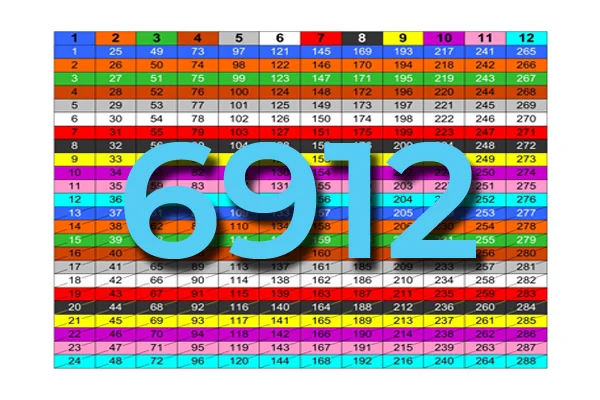

| Metric | Value |

| Average splices in a new FTTH build | 1,000–5,000 per neighborhood |

| Acceptable fusion splice loss | ≤ 0.1 dB (ideal: 0.02–0.05 dB) |

| Splicing time per joint | 30–90 seconds |

| OTDR test pass rate (Tier 1) | 95% on first splice (well-trained crew) |

| Failure rate of field splices | <2% with trained personnel |

| Feature | Fusion Splicing | Mechanical Splicing |

| Typical Loss | 0.01–0.1 dB | 0.2–0.75 dB |

| Cost per splice | Low after setup | Higher |

| Durability | Permanent | Temporary or short-term |

| Common Use | Long-haul, FTTH, OSP | Emergency, patching |

Tools of the trade: what's in a splicer’s kit?

Field technicians are modern-day surgical artists – and their toolkits are surprisingly sophisticated.

Typical OSP splicing kit includes:

Fusion splicer

Cleaver with diamond blade for clean 90° cuts

Fiber strippers for jacket, buffer, and coating removal

VFL (Visual fault locator) to light up broken fiber

OTDR (Optical time domain reflectometer) for splice testing

Heat shrink oven to protect splice sleeves

Isopropyl alcohol + lint-free wipes (the golden combo)

Battery banks to stay online in remote areas

💡 Did you know? Many techs personalize their splicers with decals, names, stickers – because when you splice 400+ fibers a day, it becomes your partner.

Real-world OSP splicing challenges

1. Hurricane recovery splicing

After Hurricane Maria in Puerto Rico, fiber teams used helicopters to access mountainous regions and hand-spliced lines in open rain, under tarps held by local residents. Some lines had to be re-spliced every few weeks due to mudslides and erosion.

2. Wildlife interference

Squirrels are infamous for chewing through aerial fiber – creating frequent emergency splicing jobs. In Australia, cockatoos have been known to shred fiber jackets, requiring full retrenching and re-splicing jobs.

3. Underground vaults in urban areas

Technicians in places like NYC and London often work in waist-deep water, splicing cables that run under centuries-old infrastructure – sometimes next to steam pipes, sewer lines, and electrical hazards.

Conclusion, kind of

While it may not have the glamour of data centers or the hype of satellites, fiber splicing is the invisible foundation of digital life. It connects cellular towers to operator networks, hospitals to cloud services, financial firms to stock exchanges, and families to video calls across the globe.

Next time you binge Netflix or make a video call, remember: somewhere out there, a technician may have spliced those fibers in a muddy trench, inside a manhole, or during a snowstorm – with perfect precision.

And there’s a lot to come and to anticipate in the world of fiber fusion splicing.

Scientists are now studying how DNA strands repair themselves to improve AI-based automatic fiber splicing. Like DNA’s “zipper effect,” future splicing algorithms could self-correct core misalignments using feedback loops.

Researchers at MIT have developed a nano-scale fusion splicer using lasers to join optical nanowires – potentially enabling on-chip fiber networks for quantum computing.

Take care of your splice sheets

1000+ ISPs are already saving weeks of work with Splice.me!