Optical cables are not included in the list of communication equipment subject to mandatory certification, but all service providers require suppliers to provide a declaration of conformity. Current legal documents describe the areas of application of fiber optic cables, requirements for their resistance to mechanical and climatic load, as well as requirements for the electrical characteristics of optical cables with metal structural elements. For example, the allowed tensile strength of self-supporting optical cables must be at least 3 kN, and resistance to temperature effects must be ensured in the range from -75 to 150 °F.

However, the criteria for assessing resistance are not determined. The regulation only states that “attenuation in the sample shall not exceed the values specified in the regulatory and technical documentation for cables of specific brands.” At the NESC level, this is not specified in any way, but is only indicated in the technical specifications of individual cable manufacturers, which leads to an extremely ambiguous assessment of the quality of fiber optic cables.

Let’s consider an example. A service provider is holding a tender for the purchase of self-supporting optical cable that can withstand a tensile load of 15 kN. Usually commercial offers from different manufacturers can vary significantly in price. The customer checks whether the manufacturers have a declaration of conformity for this type of cable with the «Rules of Application» and selects the product with the lowest price. It would seem that everything is logical: after all, the labeling of all cables indicates the same 15 kN. In fact, the technical characteristics of cables from different manufacturers can vary significantly. For instance, the number of reinforcing aramid threads in the design of cables of «the same kilonewton strength» differed by a factor of 1.5! Of course, such cables will not have the same characteristics. The main reasons for this confusion are the vagueness of the criteria in the standards and the inability to check the stability of the purchased fiber optic cable to external influences at the installation site during initial inspection.

During initial inspection, a visual inspection and fiber attenuation measurement are performed. At the same time, the cable is inspected without mechanical and climatic loads, which makes it completely impossible to evaluate its performance at low temperatures, under the influence of ice or wind.

This primarily concerns aerial optical cables, because throughout their entire service life they are subject to cyclical temperature changes and mechanical influences. There are no such fluctuations on the reel.

The resistance of cables to external influences can only be assessed in a specially equipped laboratory. Currently there are no sufficiently equipped independent laboratories, but basically all cable factories have their own laboratories. If a clause on the possibility of conducting factory acceptance tests is included in the supply contract, the factory will be able to perform them.

But it is still not so simple: as noted earlier, the only criterion for assessing the resistance of cables to external influences in regulatory documents is attenuation, and there is no clear limit on the change in attenuation.

Thus, there is a gap in standards in defining the criteria for assessing the resistance of fiber optic cables to external mechanical and climatic influences, i.e., in defining the essential quality criteria for cables. If there are no industry-specific standards, then an international standard should be used (one of the International Electrotechnical Commission (IEC)).

IEC standards clearly specify the criteria for assessing the quality of fiber optic cables: the increase in attenuation of the optical fiber and the relative elongation of the fiber under tensile load (fiber strain). The second parameter is very important.

The fiber in optic cables is laid with a certain excess, i.e., the length of the optical fiber in the cable is slightly greater than the length of the cable itself. The reason for that is – the tensile load applied to the cable is not immediately transferred to the fiber. First, other elements of the cable are stretched, the fiber straightens, and only then it is stretched and elongated.

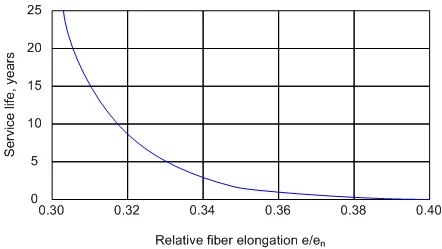

At plants producing fiber, after the manufacture, it is usually winded with a tension of 0.69 GPa, which leads to a relative elongation of the fiber by 1%, i.e., 1000 m of optical fiber can stretch by 10 m. This relative elongation is considered destructive, as there is no guarantee of fiber integrity at mechanical stresses greater than this. At the same time, the service life of an optical fiber depends on its relative elongation under tensile load.

Taking into account the fact that the service life of fiber optic cables according to the standard should be at least 25 years, the relative elongation of the fiber should not exceed 0.3%. Thus, to ensure a cable service life of 25 years, it is sufficient for the relative elongation of the optical fiber during operation to be approximately three times less than the relative elongation of the fiber during its factory rewinding.

This rule is reflected in the IEC standard for self-supporting optical cables. Thus, according to the current second edition of IEC 60794-3-20, when exposed to the maximum permissible tensile load, the relative elongation of the optical fiber must not exceed one third of the relative elongation of the fiber during rewinding (fiber proof test). At the same time, the attenuation gain must not exceed 0.05 dB.

Since the fiber proof test value is 1%, the maximum relative elongation of the fiber in self-supporting optical cables should not exceed 0.33%.

In case of underground fiber optic cables (for ducts, soil, coiled cables, and cables for river crossings and coastal laying), a relative elongation of the fiber of 0.6% is allowed for short-term tensile loads and 0.2% for long-term loads. Unlike self-supporting cables, which experience high tensile loads repeatedly throughout their service life, other cables experience them only at the time of installation.

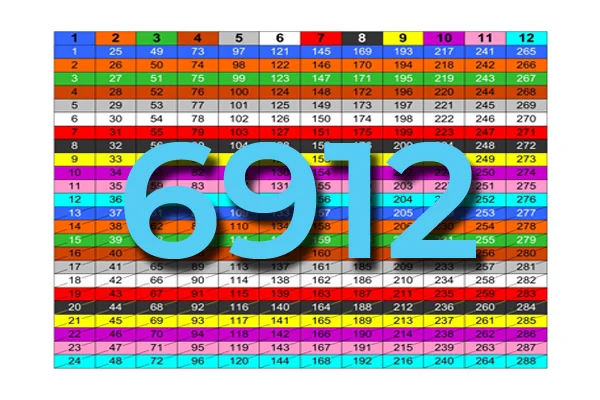

Let’s summarize the criteria for assessing the quality of OK cables in a single table:

| Cable type | Allowable relative OF elongation during short-term load | Allowable relative OF elongation during long-term load | Standard |

| ADSS & type-8 | 0.33% | Not specified | IEC 60794-3-20 |

| Undeground, duct, overlsh | 0.60% | 0.20% att. gain ≤0.05 dB/km @1550nm | IEC 60794-3-11 |

| Submarine | 0.60% | 0.20% att. gain ≤0.05 dB/km @1550nm | IEC 60794-3-30 |

However, factories often supply fiber optic cables which quality is significantly worse than required by the standards.

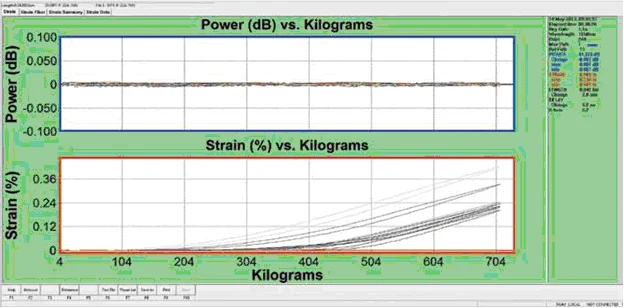

Pic.2 shows the results of tests on a self-supporting FO cable with a declared maximum tensile load of 7 kN. The upper graph describes the change in attenuation in 12 fibers selected from a 32-fiber cable, while the lower graph shows the relative elongation of these same fibers. It is clearly seen that the relative elongation of the fiber (Strain) at the declared load of 7 kN (700 kilograms) was 0.45%, which is 1.5 times higher than the norm. Although no increase in attenuation (Power) is observed, the service life of such fiber will be short. When measuring the attenuation of the fiber in the cable during the initial inspection, such a defect cannot be noticed: tests in a production laboratory are required.

Some factories produce self-supporting fiber cables that provide a relative elongation of the fiber of 0.7% at the maximum permissible tensile load. Not only is this more than twice as bad as the norm, but according to Pic.1, such cable will be practically unusable. Some manufacturers even use the breaking strength (RBS) of the cable in their labeling instead of the maximum permissible load. It is impossible to check this during incoming inspection. Manufacturers are apparently hoping that maximum climatic impacts occur only once every 20 years, and the warranty period for cables at many factories is only 1 year, so the likelihood of warranty obligations being fulfilled is low. But is it worth it for a service provider to invest in infrastructure built on such cables? Wouldn’t it be better to organize a more rigorous selection process of suppliers and inspection of cables at the factory lab?

Of course, there are serious factories that value their reputation and very carefully control the quality of their products. The requirements for the permissible relative elongation of fiber in cables from such manufacturers are stricter than the standards in order to ensure a certain margin of cable reliability.

It is worth noting that, contrary to popular belief, Chinese industry standards are stricter than international ones. Table 2 provides a translation of the quality assessment criteria for self-supporting fiber optic cables from the Chinese national standard.

| Name | Tensile load | FO deformation in central tube, % | FO deformation in module, % | Attenuation in central tube, dB | Attenuation in module, dB |

| RTS (rated tensile strength) | ≥95% RTS | – | – | – | – |

| Max. allowable tension | 40% RTS | ≤0.1 | ≤0.05 | N/S | N/S |

| Everyday load (average year-round tension) | 25% RTS | N/S | N/S | N/S | N/S |

| Ultimate operation strength | 60% RTS | ≤0.50 | ≤0.35 | No residual tension | No residual tension |

However, these requirements are only mandatory for the domestic China market. When exporting outside the country, manufacturers have the right to produce cables according to the customer’s technical specifications. Easy to guess that some of the cable supplied to USA has lower quality requirements. Chinese manufacturers aren’t at fault, but the importer is, who turns a blind eye to product quality in pursuit of low prices.

Conclusions

The criteria for assessing the quality of fiber optic cables are not described in sufficient detail. It is necessary to take into account both the increase in attenuation and the relative elongation of fibers at a given cable tensile strength.

It’s necessary to use international standards, taking into account that they are periodically updated. Upon initial inspection of fiber optic cable, it is necessary to check the factory test lab results that demonstrate the cable’s resistance to mechanical and climatic influences. Do not rely on fiber attenuation on the reel under normal environmental conditions solely.

Take care of your splice sheets

1000+ ISPs are already saving weeks of work with Splice.me!